[ad_1]

Printed 06-23-22

Submitted by Henkel

When a car’s fashion and performance acquire middle stage, adhesive and materials remedies function powering the scenes to make the driving experience safer, additional cozy and far more sustainable. In reality, in the modern day car, you’ll find all over 300 adhesive programs.

As a primary world wide provider of adhesives, coatings and sealants, Henkel is dedicated to furnishing ground breaking methods that generate sustainability across the automotive sector.

Lightening the Load

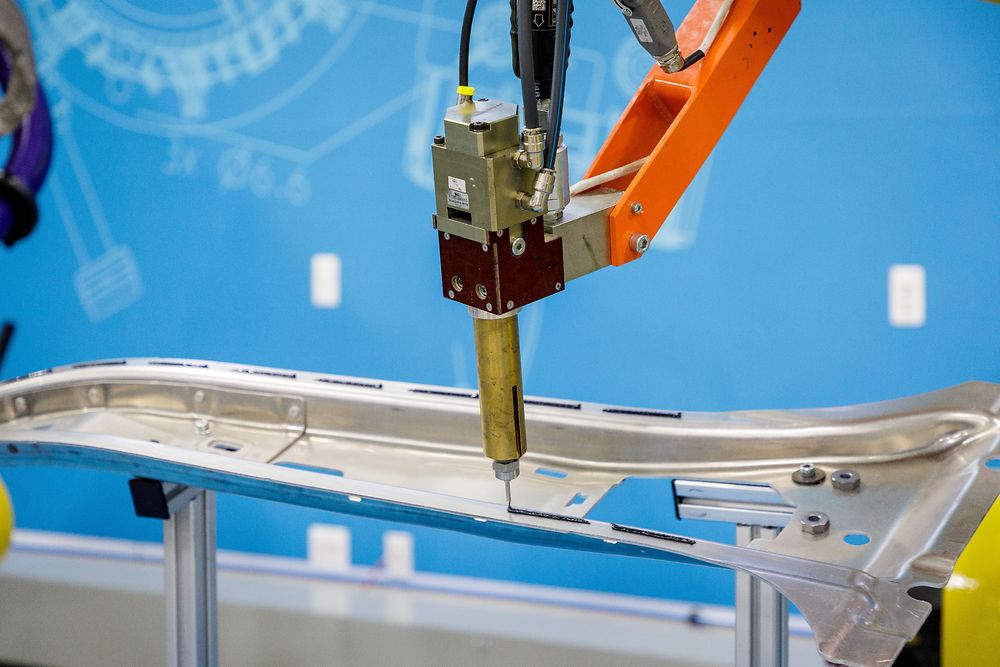

With a portfolio of sturdy, long lasting, bonding applications, Henkel’s adhesives allow for automakers to cut down car weight, though maintaining basic safety criteria and effectiveness. Making use of just 2.2 kilos of adhesives as an alternative of heavier rivets and welds can minimize motor vehicle body weight by 55 pounds.

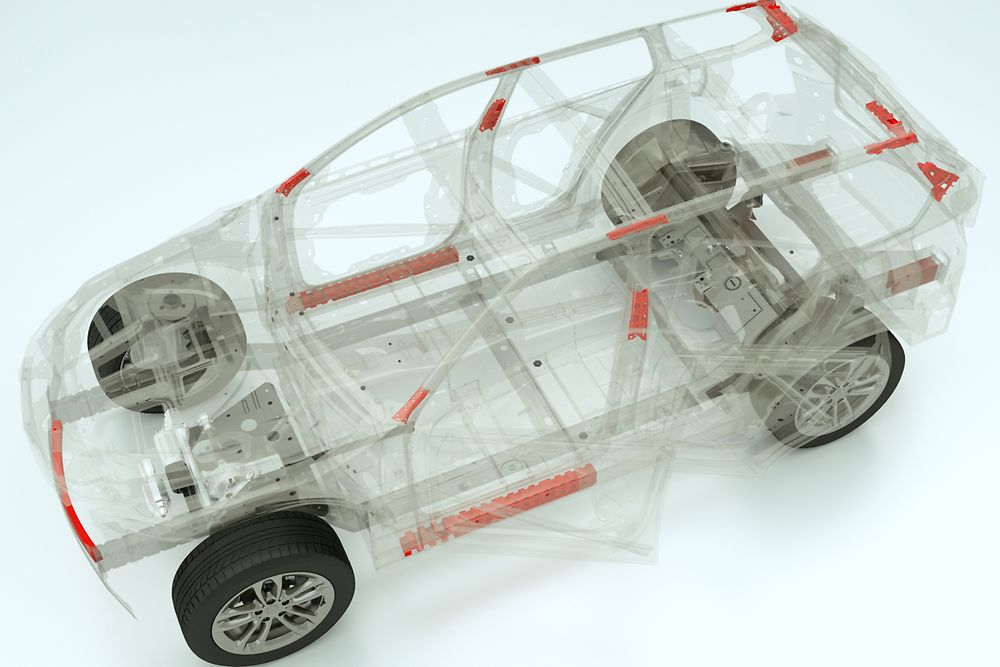

Lightweighting is an crucial strategy to help the auto marketplace address environmental restrictions about fuel effectiveness and emissions, even though continuing to enhance consolation and basic safety for the driver. As makers ramp up electric powered auto (EV) output to meet up with buyer desire, lightweighting only grows in relevance and adhesives engage in a significant role.

At this time, electric vehicles are roughly 30 percent heavier than traditional gas-run vehicles. This is largely because of to the body weight of the battery, which spans the length of the car or truck system. The use of extra lightweight elements in EV manufacturing aids to offset the weight of the battery and increase driving assortment — a critical advertising place for consumers.

Structural inserts and steel pretreatments also aid lightweighting and assist Henkel pave the way for more sustainable vehicles.

Structural Inserts

Intended for a wide assortment of utilizes, Henkel’s structural foam elements aid enhance motor vehicle safety although also decreasing excess weight and production fees. Injection-molded onto plastic or metallic carriers, Henkel’s 3-dimensional structural inserts can be applied to switch heavier pieces, these kinds of as steel bolts, welding or panels.

In addition to providing crash general performance checks that match the functionality of metal, structural foam resources act as insulation to assist decrease automobile sounds and vibration for a smoother, a lot more comfy ride.

Henkel‘s structural inserts proved the great answer when Hungarian-primarily based automaker Magyar Suzuki Corporation was searching to make improvements to lightweighting and overall body stiffness (which aids in vehicle manage, security and convenience) in its new S-Cross design. This is the to start with design globally for the Suzuki Team that will integrate structural inserts of any type. This method is generally seen in other North The united states OEMS and globally.

Next-Generation Metallic Pretreatment

Much more than four million vehicles are pretreated every year with Henkel’s Up coming Generation Steel Pretreatment approach. Numerous years of study led Henkel to the zirconium oxide-centered conversion coating, which offers a extra sustainable alternative than the common zinc phosphate pretreatment course of action.

Henkel’s award-winning pretreatment performs properly throughout metallic types, allowing automakers to introduce up to 100% aluminum on motor vehicle bodies, which is lighter than the regular metal. More environmental benefits contain elimination of large steel phosphates and up to a 90 p.c reduction in sludge technology*. Compared to a standard steel pretreatment, Henkel’s process also reduces the measures essential from 7 to four, appreciably cutting down the automaker’s carbon footprint.

The Mobility Alliance

To build sustainability into car layout from the floor up, Henkel partnered with RLE Global, a planet chief in the provision of engineering growth and technology companies, to type The Mobility Alliance in 2018.

Simply click listed here to view a video on the Mobility Alliance optimization approach.

This strategic partnership blends Henkel’s material science know-how with RLE’s engineering abilities to create sustainable answers in every move of the producing procedure — from strategy through output. In a the latest pilot challenge performed by the Alliance, the fat of an electric powered SUV was lowered by about 10%, and the amount of rivets and welds by 6%, by incorporating structural adhesives.

Sustainable remedies like these engage in a vital job in encouraging automakers and shoppers lessen their environmental impact. And Henkel will keep on to put the pedal to the metallic to get lightweighting to new degrees.

Browse this news launch for additional facts about Henkel’s progressive pretreatment method for the auto sector.

*As opposed with regular zinc phosphate pretreatment procedure

Henkel

Henkel

About Henkel in North America

In North The us, Henkel operates throughout its three small business units: Adhesive Systems, Magnificence Treatment, and Laundry & Property Care. Its portfolio of nicely-recognized shopper and industrial brand names includes Schwarzkopf® hair treatment, Dial® soaps, Appropriate Guard® antiperspirants, Persil®, Purex®, and all® laundry detergents, Snuggle® fabric softeners as perfectly as Loctite®, Technomelt® and Bonderite® adhesives. With profits of about 6 billion US dollars (5 billion euros) in 2019, North The us accounts for 26 p.c of the company’s world wide income. Henkel employs roughly 9,000 men and women across the U.S., Canada and Puerto Rico. For a lot more information and facts, you should visit www.henkel-northamerica.com, and on Twitter @Henkel_NA.

About Henkel

Henkel operates globally with a perfectly-balanced and diversified portfolio. The firm retains top positions with its a few company units in both equally industrial and customer organizations thanks to solid models, innovations and systems. Henkel Adhesive Systems is the world-wide chief in the adhesives sector – throughout all business segments around the world. In its Laundry & House Care and Beauty Care firms, Henkel holds main positions in many marketplaces and categories all over the entire world. Launched in 1876, Henkel appears again on much more than 140 years of achievement. In 2019, Henkel noted income of extra than 20 billion euros and adjusted functioning income of a lot more than 3.2 billion euros. Henkel employs more than 52,000 folks globally – a passionate and hugely numerous workforce, united by a powerful organization society, a popular goal to generate sustainable value, and shared values. As a regarded chief in sustainability, Henkel retains top positions in several international indices and rankings. Henkel’s desired shares are listed in the German stock index DAX. For much more facts, make sure you visit www.henkel.com.

Additional from Henkel

[ad_2]

Source connection

More Stories

Auction Sites Other Than eBay

Why Do Some People Have Several Different Sizes of Subwoofers in Their Car?

Introduction to Auction Websites